Quality Assurance

Piesia Electronics serves customers with the core values of "integrity, innovation, collaboration, high quality, dedication, and win-win". Relying on strong R&D and technical strength, professional and flexible product manufacturing capabilities, strict quality management system, and a global sales and technical service network.

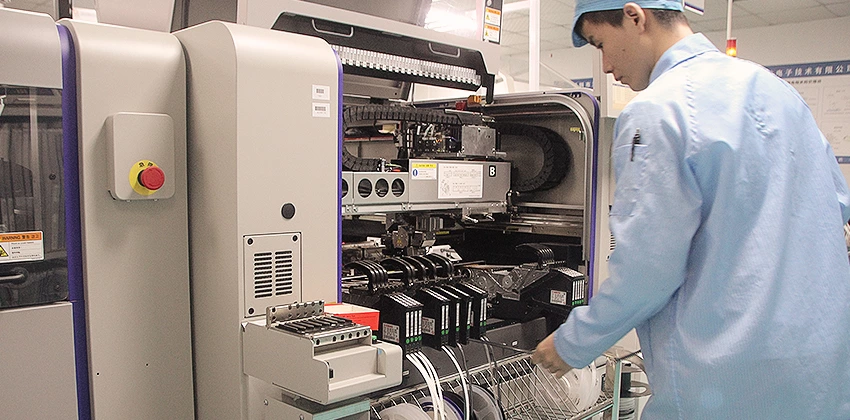

Equipped with X-RAY detector, AOI, SPI testing equipment, and testing equipment for product aging, high and low temperature, vibration, drop, two-dimensional, plugging life, key life, 4G/5G, etc.

R & D and design: In addition to meeting the special requirements of users and routine functional testing, Piesia Electronics also adds high and low temperature tests, compatibility verification, reliability testing, ESD anti-static, and product full-load testing to ensure that the products designed and produced can perform well. Work well in harsh environments.

Incoming material inspection: Before the materials required for the product are put into the warehouse, they are strictly inspected by Piesia Electronics IQC according to the incoming material standards. All materials comply with ROHS specifications. It is confirmed that all materials put into production are qualified, and the quality of the finished product is guaranteed.

Production inspection: IPQC will follow up the production processes to ensure that personnel operate according to standard specifications, find out the reasons with relevant quality and engineering personnel in a timely manner, and provide immediate solutions, and continuously improve SOP. Supervise the production unit to test and verify the product 100%. Make sure the products are all fully qualified.

Reliability testing: Piesia Electronics has a special laboratory for reliability testing. Each batch of products produced requires reliability testing. The products are verified through aging tests, drop tests, etc. to ensure that the products meet the design requirements.

Shipment inspection: Before the products produced by Piesia Electronics are put into the warehouse, the quality personnel must simulate the client to verify that there is no problem and meet the customer's requirements. After passing the warehouse, analyze the unqualified products and make solutions and rework plans to ensure shipment Each batch of products meets customer requirements.

After-sales data analysis: Piesia Electronics has data analysis, analyzes the defective products returned by the client, finds out the reasons for the failure, and conducts statistical analysis to solve problems in a targeted manner, improve the quality of the company's products, and meet the needs of customers.